AI Technology and Industry Influence: AWP Safety is Transforming Traffic Control

Consulting firm McKinsey predicts that by 2030, enterprises will reach a point of “data ubiquity” when data will be completely embedded in every system and process. Data will identify improvement opportunities and automate activities ranging from scheduling to supply chain planning.

“Companies that embrace digital change will become the greatest influencers in safety and add the greatest measurable value for customers and the public,” says Jarrod Wachter, chief operating officer at AWP Safety.

“At AWP Safety, everything we do is focused on enhancing worksite safety, improving customers’ productivity and making it easier for them to accurately forecast their operational costs,” Wachter continues. “Combining the best of human expertise and AI- driven processes is the way to do it.”

‘Digitally frictionless customer experience’

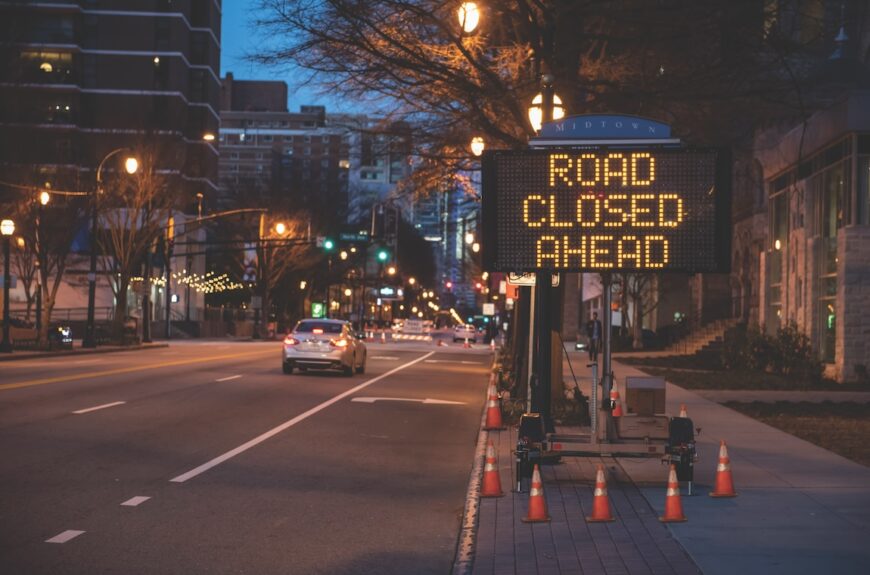

Today, many traffic control providers still rely on Excel spreadsheets and paper job tickets to plan work and deploy crews. But old school approaches don’t cut it in the complex world of infrastructure where a broadband company may need 100 traffic control crews deployed across three states on the same day — or a state Department of Transportation needs support for an 18-month highway upgrade spanning 30 miles.

According to Wachter, AI allows infrastructure companies to gain better service and valuable business insights from their traffic control partners. AWP Safety is currently implementing an enterprise digital transformation to enable this level of partnership with utility, broadband and road construction customers.

“We’re creating a digitally frictionless experience,” he says. “It allows for traffic control to become more integrated with customers’ processes to address more pain points.”

Those pain points start with how traffic control is ordered. AWP Safety is implementing several automated technologies to make it easier, including a powerful self-serve customer portal and an AI-driven telecommunications system for easy traffic control scheduling by phone.

After a customer request is received, it will trigger a chain of automated, integrated activities to serve the customer. These actions will be driven by a sophisticated Enterprise Resource Planning (ERP) system that leverages AI and machine learning to streamline internal operations and elevate delivery to customers.

“We used to rely on swivel chair integrations to push information through operations, which can leave processes vulnerable to human error,” Wachter says. “Our new digital ecosystem will cascade data faster and more accurately. “Another major pain point in our industry is billing,” he continues. “Using computer vision approaches, we can validate worksite setup to generate more accurate, timely invoices that offer insights for future budgeting.”

Tech-Driven Fleet Management

AWP Safety leads the traffic control industry in its adoption of Samsara technology for work trucks. The company was recently recognized as one of Samsara’s 100 Fleet Operators to Watch, which celebrates those driving innovation, excellence and safety in fleet operations.

Samsara dashcams gather information to help AWP Safety operations and training teams optimize driver behaviors and safety patterns across the enterprise. The data drives targeted instruction and mentoring that helps team members adopt the safest driving behaviors known today. This approach has vastly improved the company’s safety metrics related to harsh events, in turn improving public safety everywhere AWP

Safety operates.

Tech-Driven Safety

AWP Safety expects to cover 1.2 million worksites in 2025. Technology and AI will help enhance the coverage and safety of those sites – and collect a broad array of real-world data points. This information could be used to inform decisions on everything from how to reduce traffic incidents and congestion to understanding how weather and air quality impacts traffic.

“We have an opportunity to aggregate different types of information that could become the richest traffic safety data set in the world,” Wachter says. “Sensor-enabled technology like smart barrels and signs can collect metrics like traffic flow, density and volume, vehicle classifications, worksite set-ups and environmental conditions. All of it can help us, customers, safety experts and legislators make better decisions that save lives.”

AWP Safety has already helped customers achieve greater worksite safety by deploying Smart Work Zone technologies like Automatic Flagging Assistance Devices (AFADs). Using WAZE technology to share information with motorists through GPS, AFADs can divert up to 25 percent of traffic around a worksite entirely, further reducing the chances of an accident. It’s a mini case study in what could be possible in the future, when all traffic control equipment is digitally connected.

Finally, robust AWP Safety systems already automatically predict traffic control coverage needs based on customers’ real-time scheduled job data – and generate accurate traffic control plans (TCPs) within a short 24 hours.

Wachter notes that the next generation of work zone safety technology will be driven by collaborative research among safety experts, infrastructure companies and academia. The Construction Safety Research Alliance (CSRA) at the University of Colorado brings these groups together and conducts scientific research focused on eliminating serious injuries and fatalities in the construction industry. AWP Safety is the sole CSRA member representing the traffic control industry and is a crucial voice for driving new academic research on traffic control technology.

“We’re excited about the possibilities,” Wachter says. “It’s all about solving problems together to save lives and improve efficiency.”

Are You Ready for the Future?

Wachter says it’s crucial for infrastructure companies to ensure they have a strong technology foundation before embarking on their own technology journey. Here are a few tips:

Learn more about how AWP Safety leverages Smart Work Zones, and the latest technologies!