Customer-Driven Procurement

In industries as dynamic and fast-paced as safety and traffic control, it’s common for companies’ procurement teams to stay focused on meeting immediate needs. AWP Safety’s more strategic approach to integrated supply chain management adds longer-term value, for the company’s operation and for customers.

Q: Dwayne, what’s your background? How is it helping shape AWP Safety’s approach to procurement?

I’ve been in procurement for 30 years. In that time, I’ve gained experience in sourcing, purchasing, supply chain, and materials management for large manufacturing companies. The manufacturing industry is very advanced in its procurement strategies, and many of those best practices are transferable to industries like safety.

At AWP Safety, we look holistically at our procurement ecosystem, leveraging data and vendor partnerships across the enterprise to streamline our supply chain in ways that help us operate more efficiently and deliver outstanding customer service. It’s my goal to make AWP Safety the safety industry’s gold standard in procurement.

Q: How do customers drive your procurement strategy?

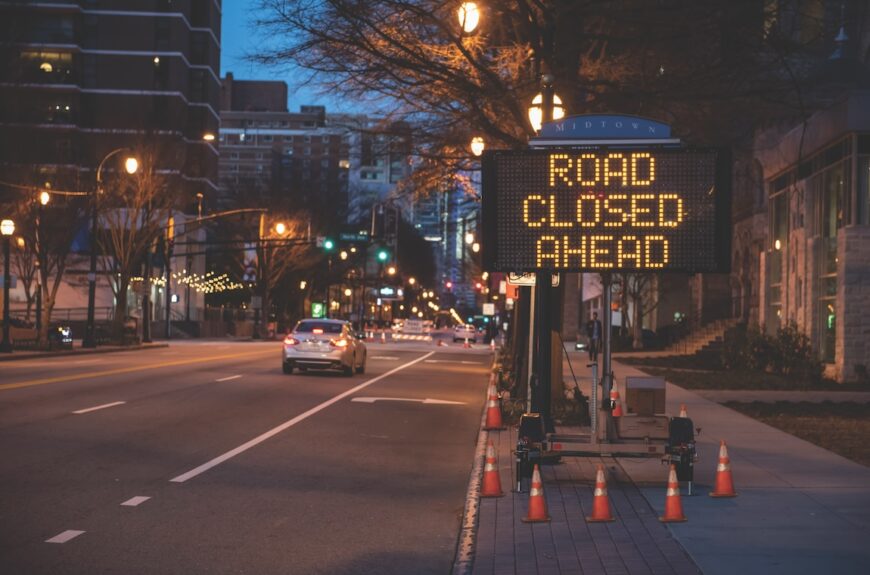

We always want to say “yes” to our customers and deliver quickly on what they need. Through our procurement strategy, we’re achieving an integrated supply chain that is seamlessly connected and ready to serve customers at a moment’s notice. For example, customer Texas A&M Transportation Institute (TTI) is supporting a 10-year roadway Texas Department of Transportation (TXDOT) reconstruction project by completing a major traffic and road conditions survey. The survey work bubbled up quickly, and because of our supply chain, we were able to deliver a high-quality Intelligent Traffic System (ITS) within 24 hours of TTI’s request. The ITS includes 18 automated messages boards that support a complex end-of-queue warning system to elevate driver safety.

We also want to make smart, efficient supplier decisions that ultimately benefit our customers. Procurement teams that work in silos can make an impact, but that impact will be limited. Our approach is to leverage cross-functional teamwork – from our executive team to finance to our partners in Environmental, Health and Safety – to make supplier decisions that improve the level of quality and speed we provide for every customer.

Q: How does procurement strategy improve quality?

We hold our suppliers to an extremely high standard. We don’t just look at price; we insist on quality and performance excellence and will adjust our list of suppliers if it means we can achieve a higher level of product quality or access more advanced safety technology. One example is automated flagger assistance devices (AFADs). We’re currently transitioning to a supplier with an AFAD offering that affords more opportunities to standardize our equipment and better manage maintenance on the units. These are benefits that translate to worksite efficiency and shorter lead times for customers.

Q: Do you collect and use data to make these decisions?

Absolutely. Data helps us forecast what our customers need and when they need it. The safety industry can be unpredictable sometimes – one major hurricane can disrupt the normal flow of utility work for weeks. But there are historical trends we use to make data-driven decisions for better planning. And we track equipment performance to ensure it’s living up to the claims and our customers’ expectations.

We also leverage key performance indicators (KPIs) to understand if our suppliers are hitting benchmarks or improving year over year. It’s been a game changer.

Q: What’s the future of AWP Safety’s supply chain look like?

In a word, seamless. I often reference an image of figures linked arm-in-arm that represents AWP Safety, our suppliers, and our customers.

I envision a supply chain so well-connected that customers know that any solution they get from us will be of the highest quality, arrive at the

right time, and fit their budget. They know that we’ll be ready to rock and roll on whatever they need from us.

Learn more about ITS and other Smart Work Zone solutions mentioned in this article,